Inventing A New Socks

I used to work as a roofer, where I would climb up and down roofs, install gutters, and patch holes. One day, my boss instructed me to use copper nails when working with copper gutters, but he never explained why. This left me wondering, why are copper nails so important for this task?

One fine day, destiny led me to a service call at a magnificent multi-million dollar house. Little did I know that this would be the day when I finally unraveled the mystery. As I examined the gutters, I noticed something peculiar—the steel nails holding the copper gutters in place had completely rusted, and they were only five years old! How could this be?

Thanks to my curious nature, I embarked on a quest to understand this phenomenon. It turns out that this process is called galvanic coupling. When rainwater comes into contact with the copper gutters and the steel nails, it creates a potential difference, much like a battery. This potential difference initiates the movement of electrons between the metals.

Copper Emits Copper Ions

Fascinatingly, copper, being the superstar with a higher potential, becomes the cathode in this scenario, while poor iron (found in those steel nails) becomes the anode, lagging behind. This leads to a decrease in the corrosion rate of copper but significantly increases the corrosion rate of iron. Consequently, the steel nails rust away much faster than the copper gutters, posing a threat to the stability of the entire system. Imagine a premium copper gutter just falling off due to this corrosion—certainly not what we want, right?

Now, while all of this had me pondering the wonders of copper and its magical properties, I couldn't help but wonder if the same principle could be applied to another problem—foot fungal infections.

You know, those pesky conditions like athlete's foot and toenail fungus that trouble so many people.

Cotton + Copper

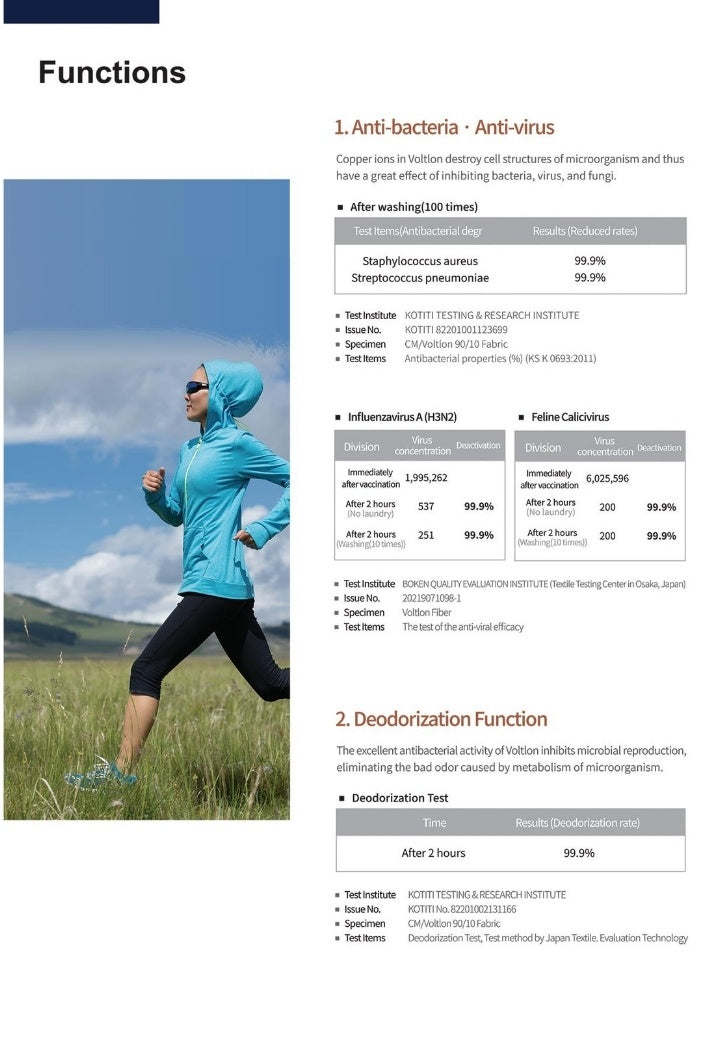

Drawing inspiration from copper's antimicrobial effects, I embarked on a new mission—to create something extraordinary. Copper-infused toe socks were my vision. Lucky for me, copper fibers had already come a long way, especially during the COVID-19 pandemic when their antibacterial properties gained widespread attention. There was a treasure trove of research, experimental data, and a multitude of products already available.

But here's the catch—I found it challenging to find a knitting factory willing to make socks with a high copper content. They kept emphasizing the importance of comfort and were hesitant to go beyond 20% copper. I, however, believed that more copper would yield better results. Sure,I understand their concerns about stiffness, discomfort, copper odor, shrinking after washing, and falling down. but I couldn't simply give up.

After much contemplation, a brilliant idea struck me like a lightning bolt! What if I placed copper fibers only on the toes and made the rest of the sock with soft and comfortable cotton? That way, the socks would maintain overall comfort while ensuring a substantial amount of copper specifically where it was needed—the toes. And thus, Copperfinger socks were born!

The Partners

I brought this idea to the manufacturer, but I encountered another problem. It was difficult to produce the socks.

We were unsure of the appropriate amount of copper to use in our fabric. Initially, we mixed it in a 50:50 ratio, but when we tested the fabric by breathing on it, it did not breathe well. To address this issue, we reduced the ratio to 45:55 and tested it again. This time, the fabric breathed better, felt good, and did not shrink after washing and drying. We believe that 45:55 is the sweet spot, so we will continue using this ratio for now. However, we are still exploring ways to enhance the fabric's breathability with more copper.

Although we had figured out the ratio, we still faced a lot of problems. The manufacturing process was entirely new, and most sock manufacturers were unable to invest in another machine and conveyor line to process this new item. They were too busy running their existing products and too tight on budget to do so. Sadly, nobody wanted to make these socks. At this moment, we had no choice but to close this project until I had an idea.

The idea was to find a manufacturer who could share the process. I had to find a manufacturer who could make the toes with copper, another manufacturer who could make the body part with cotton. another manufacturer who could put them together, and another manufacturer who could package the socks. It took me almost 18 months to find all these manufacturers. It was a long time, but by doing so, we were able to process this product.

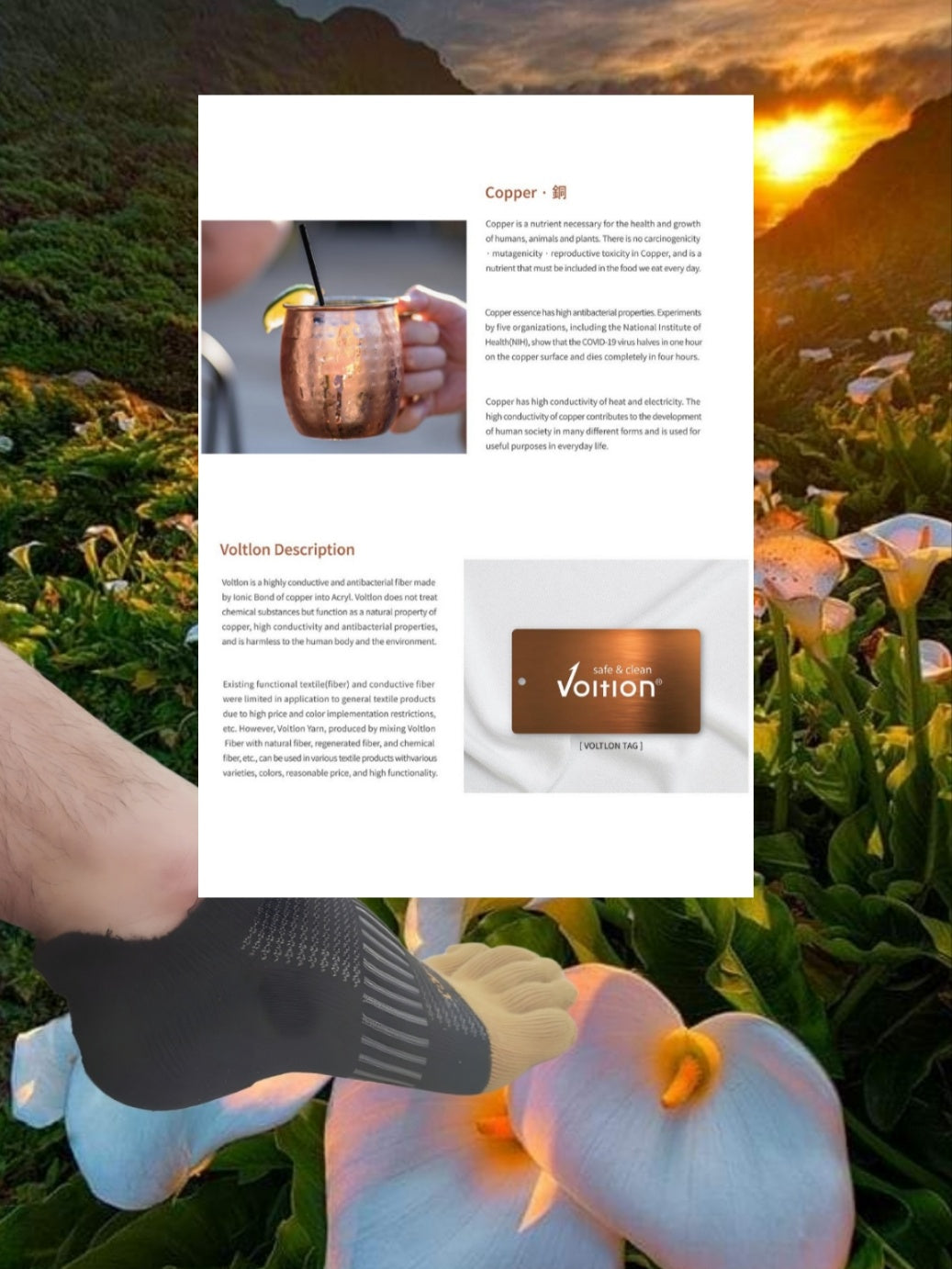

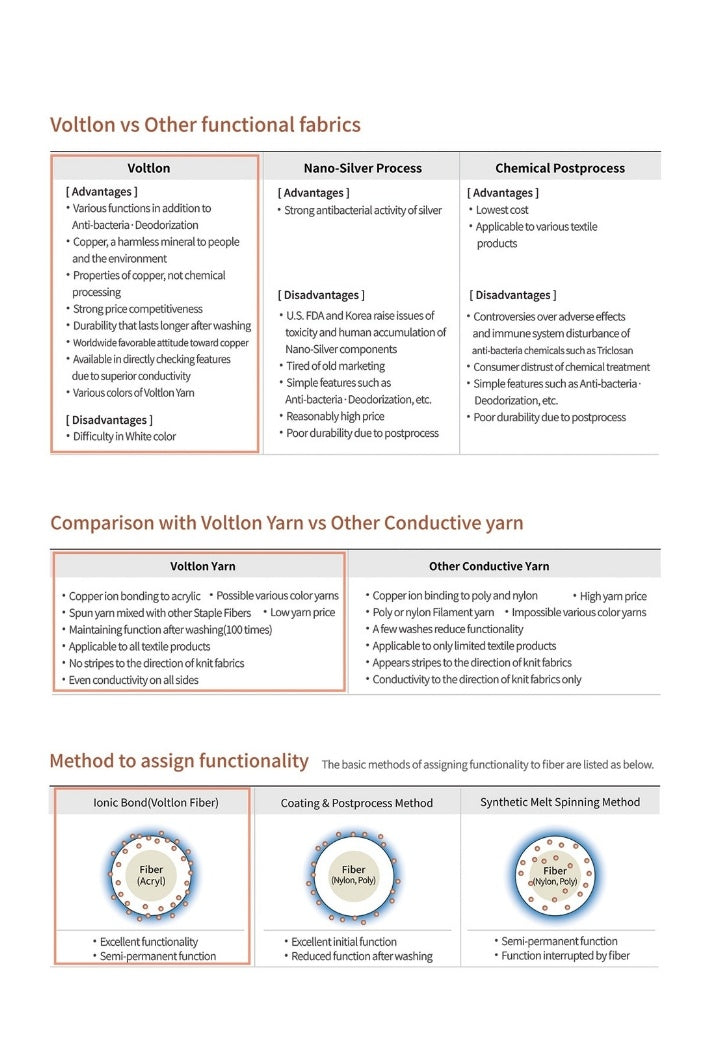

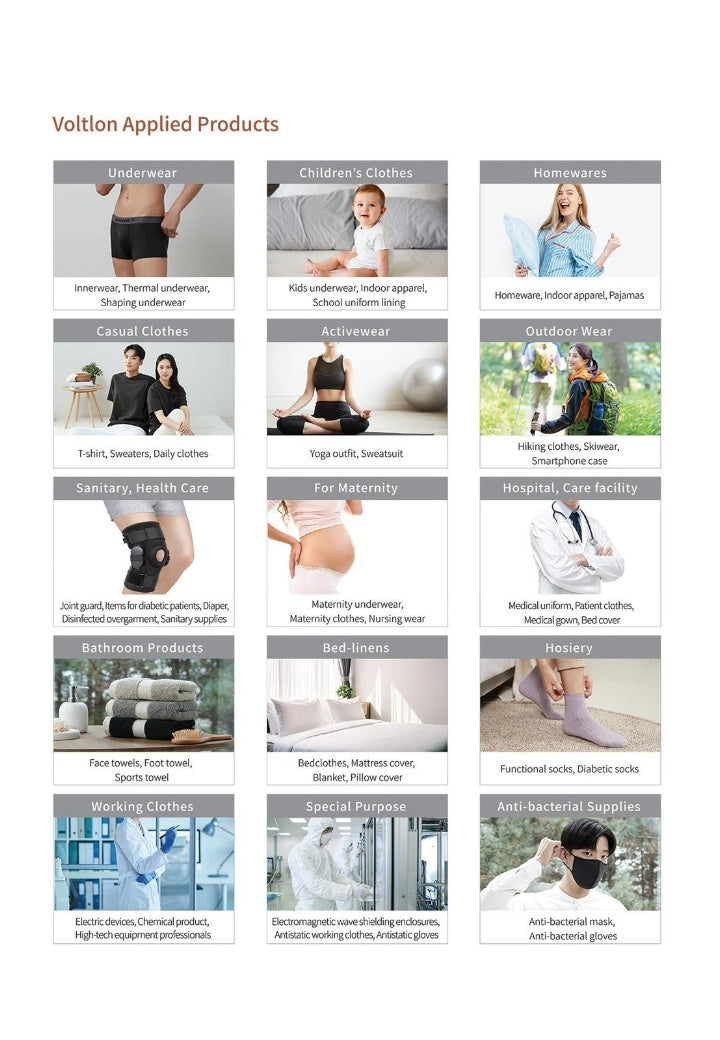

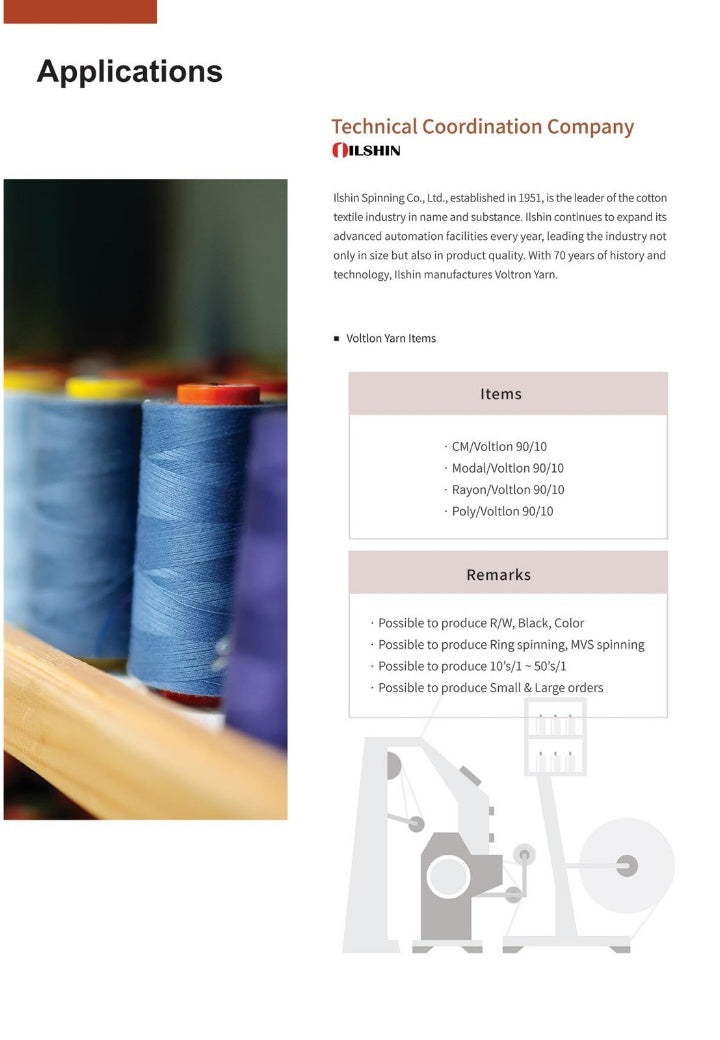

We thank you one of our most important manufacturers in Korea Voltlon, which produces copper-infused fiber toes for us. Their electrospinning copper-infused technology is considered to be the best in the world.

So Far

We have made good progress with this product, but we still face many challenges. Our biggest hurdle is our price tag. We know there are many other sock companies out there where you can buy dozens of socks at the price of our tag. We respect all the hardworking people and thank them for their service. We hope they will wear our socks to make their feet feel fresh again, purchasing them at a good price.However,We apologize that we are unable to manufacture socks on a mass production level at this time, as we are a startup. However, we are continuously seeking opportunities to donate Copperfinger socks to police officers and firefighters. If you are one of them, please let us know. We look forward to hearing from you and appreciate any messages. Thank you.